focus on robot ODM

News

EN

Fdata's mobile robot chassis is the perfect solution for those looking for a reliable and versatile robot platform kit. With its heavy duty construction, this wheeled robot platform is capable of carrying a wide range of payloads, making it ideal for a variety of robotics applications.

Featuring a sturdy frame and durable wheels, this mobile robot platform is built to withstand the toughest conditions. It is also fully customizable, allowing users to add or remove components as needed for their specific projects.

In addition to its strong construction and customization options, Fdata's mobile robot chassis also boasts a number of convenient features. Its easy-to-use robot chassis design makes it simple to assemble, while its compact size makes it easy to transport and store when not in use.

Overall, if you're looking for a versatile, heavy duty robot chassis that can be customized to suit your needs, look no further than Fdata's mobile robot platform kit. With its strong construction, convenient features, and exceptional performance, it's the perfect choice for a wide range of application of robotic process automation.

Fdata is your trustworthy robot solution partner with our Outdoor Robot Platform and Indoor Robot Platform. We are here to help your business grow.

.

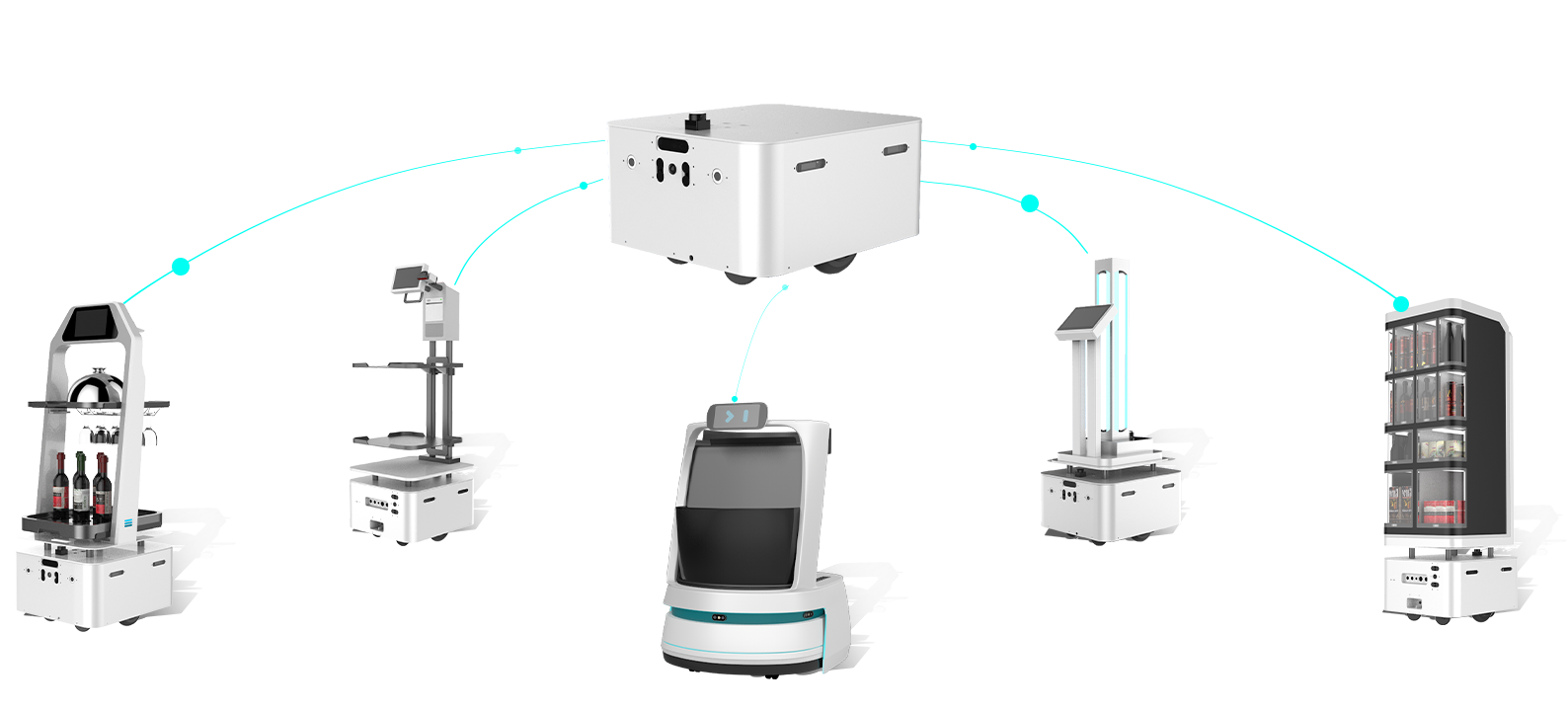

With DIY autonomous robot platform, the client can add any functioning part above, and then make a different mobile service robot.

With smart 3D sensors, the mobile robot platform can aware of obstacles at any angle, and keep moving.

When in a state of low power, the autonomous mobile platform will return to the docking station and charge automatically.

Equipped with a smart chips, human-robot interaction changed to be more wonderful.

Combining lidar SLAM and visual SLAM, mobile robot chassis get simultaneous localization and mapping.

Fdata's autonomous mobile platform support fixed-route setting and autonomous route setting.

By the antiskid design at the bottom, the robot platform can move on the slippery road.

The IoT module equipped inside robots and elevators can make mobile robot chassis easily enter and communicate.

LiDAR SLAM and Visual SLAM are advanced mappings and positioning technologies that are commonly used in professional service robots.

LiDAR SLAM uses lasers to create detailed 3D maps of the environment. The LiDAR sensor emits laser beams and measures the time it takes for the beams to bounce back off objects in the environment. By combining these measurements, the heavy-duty robot platform can create a detailed map of the environment in real-time. This map can then be used to navigate the robot through the environment with greater accuracy and speed.

Visual SLAM uses cameras and computer vision algorithms to estimate the robot's location and create maps. The camera captures images of the environment, and the computer vision algorithms analyze these images to create a map. The algorithm tracks the robot's movements and uses the changes in the environment from the camera images to update the map. This allows the robot to navigate through the environment with greater accuracy and speed.

Both LiDAR SLAM and Visual SLAM are important technologies for mobile robot base, as they allow the robot to navigate autonomously through complex environments. These technologies can be used in a variety of smart robot solutions such as robotic process automation in warehouses, inspection, and robot security guards, where mobile robot chassis need to move quickly and safely through cluttered environments.

Looking for a mobile robot platform application? Discover the versatility of a DIY robot platform designed to meet your specific use scenarios. Build your own customizable robot with our platform, tailored to your needs. Explore endless possibilities with a mobile robot platform kit that empowers your creativity and innovation.

Wheels: prepare for the in-wheel motor drive.

Prepare for mobile robot chassis and housings

Preparation of IPC, battery, control board, sensor, controller, wire, and other materials.

Drive wheel and universal wheel assembly.

Industrial control machine, battery, control board, sensors, and controllers assembly in place.

Connect the components with wires.

Housing assembly.

Mobile heavy-duty robot platform testing.

There are several common types of robot mobile platforms, including 4WD, Ackermann, and 4WD-4WS. Each type has its advantages and is suitable for different custom robotic solutions.

A robot mobile platform refers to a robot base or mobile robot chassis that provides mobility. It typically includes wheels or tracks, along with motors, sensors, and other components necessary for movement and navigation.

Payload capacity, mobility and terrain adaptability, speed and agility, power source, control system and integration, size and weight restrictions, and environmental considerations are important factors to consider when choosing a mobile robot chassis.

Yes, robot mobile platforms can be designed to operate autonomously. Autonomous mobile platform can incorporate sensors, perception algorithms, mapping systems, and navigation algorithms to make independent decisions and navigate their environment without constant human intervention.

The robot chassis design refers to the physical structure or framework of a robot that serves as the foundation for attaching various components and systems. It provides the structural support and determines the overall shape, size, and layout of the mobile service robot.

Mobile robot chassis can be constructed using a variety of materials, depending on the specific requirements and smart robot solutions. Some common robot chassis materials used include:

Aluminum: Aluminum mobile robot platform kits are popular due to their lightweight nature, strength, and durability. They offer a good balance between weight and structural integrity.

Steel: Steel mobile robot chassis provide excellent strength and rigidity, making them suitable for heavy-duty applications. However, they tend to be heavier compared to other materials.

Carbon fiber: The carbon fiber mobile robot chassis is lightweight, yet strong and rigid. They offer a high stiffness-to-weight ratio, making them ideal for applications that require both strength and reduced weight.

Plastic: Plastic mobile robot chassis is lightweight, cost-effective, and can be molded into various shapes. They are commonly used in smaller or low-robot chassis price applications.

Yes, it is possible to build your own mobile robot chassis. However, it requires knowledge of mechanical robot chassis design, fabrication techniques, and access to appropriate tools and robot chassis materials. DIY robot platform chassis can be constructed using materials such as metal, plastic, or wood, depending on the desired characteristics and resources available. Various online resources, tutorials, and communities provide guidance and examples for building custom robot chassis.

Yes, pre-made mobile robot chassis can often be modified or customized to suit specific needs. They often have modular designs that allow for easy integration and customization of additional components, sensors, or structural modifications. With appropriate tools and skills, it is possible to modify the chassis to meet specific size requirements, add mounting options, or make structural changes. However, it is important to consider the limitations of the chassis and ensure that modifications do not compromise its integrity or performance.

Our DIY robot platform is perfect for users looking to build their own mobile robot chassis. These heavy-duty robot platforms have easy secondary development and integration with customers' apps and other sensors, to meet the requirements of different customers on the platform for DIY custom mobile robot chassis. In addition, our open API provides users with a simple and reliable way to develop advanced robots for applications, we have a professional service robotics and technologies team to provide you with technical support including ROS support, and robot hardware support, allowing you to quickly develop your own robot chassis.

With our DIY robot chassis platform, you can quickly and efficiently program and manufacture robot mobile platforms that meet different custom robotic solutions.